|

|

NON

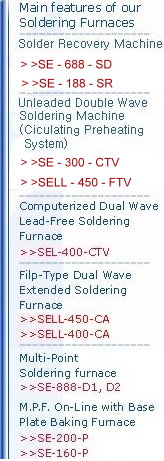

AIR COMPRESSOR FLUX SPRAYER SE-400-SPR

|

|

|

|

|

- Not

using air compressor , as a result not problem on water

accumulation.

- Fully

comprterised controlled.

- Spraying

size can accommodate up to 400mm of PCB dimension.

|

|

|

- Low

pressure control enable longer life-span for pump and ensure

smoother spraying.

- Sensor,

control for timing of PCB movement .

- Cleaning

system to prevent blocking of spraying nozzle

|

|

|

- Recycling and reusing of flux, save flux

and economical.

- Use no-clean flux for the machine.

- Using strong sucking facility to elimimate

the flux remainder.

|

|

| Type

\ Model |

SE-400-SPR

|

| Power |

AC

220V, 1ø, 50/60 Hz

|

| Control

Box |

650mm(L)

x e400mm(W) x 1000mm(H)

|

| Flux

Container |

650mm(L)

x260mm(W) x 350mm(H)

|

| PCB

Size |

20mm~400mm

|

| Pressure |

8~15

kg /cm2

|

| Solvent

Tank |

about

30 L

|

| Weight |

about

90 Kgs

|

|

|

ADVANTAGES

of SE-400-SPR

|

- Using

PLC microprocessor, the PCB length and distance of each PCB can

be precisely calculated and flux will be sprayed efficiently.

- The

enclosed flux tank allows excessive flux recover for re-use, reducing

flux amount and lowering production cost.

- The

machine can be flexibly adjusted as per flux and foggy granule

required by different PCB and it maximizes the soldering effect.

- The

distance between spray nozzle and PCB is set 5cm-10cm ,allowing

direct coating and best effect.

- Can

work with any type of soldering machine.

- Fully

automatic controlling process, compact display and easy to operate.

- An

air suction mask is specialy equipped, with a filter inside which

can be withdrawn for easily cleaning or replacing and it causes

no pollution.

|

|

|

|

|

Spraying

Effect

|

|

|

|

Control

Panel (Auto Gravity Controller(optional))

|

Spraying

|

|

|

|

Flux

Sprayer Allocation

|

|