Unleaded Double Wave Soldering Machine(Circulating Preheating System) SELL-450-CTV |

|

Environmental Peotection&Energy-Saving Soldering Machine |

|

Delta Electronic Model

|

|

|

Temperature Compensate Heater Fan(Patent) Temperature Compensate Heater Fan(Patent) |

Lift-type Double Layer Cover Lift-type Double Layer Cover |

|

| Specifications \ Model |

SELL-450-FTV |

| Power Souerre |

3Ø 220V115Aor380V 68A |

| Production |

8Hours |

2,000PCS |

| pcb Size |

250x300mm |

| Conveyor |

Speed |

0∼2400mm/min. |

| Tilting Angle |

5°∼ 6.5° |

| Preheater |

Power

Consumption |

44KW |

| Temperature Range |

0℃~250℃ |

| Heater Fan |

Power

Consumption |

6.6KW |

| Temperature

Range |

0℃~220℃ |

| Solder

Pot |

Power

Consumption |

13.8KW |

| Temperature

Range |

0℃~399℃ |

| Nozzle Width |

0∼400mm |

| Flow Height |

0∼10mm |

| Solder Capacity |

approx450Kg |

| Motor |

120W x 2 |

| Machine Weight |

approx.2800Kg |

|

|

| |

|

The angle conveyor be adjusted by touching.(The angle can be shown) |

|

Programmable temperature control by PID operation |

|

Use an energy-save electrical device to adjust solder pot level. |

|

Electrical control to move the pot in and out; easy for maintenance. |

|

Electrical control the conveyor width to fit PCB |

|

High pressure solder wave nozzle, better soldering result to unleaded PCB |

|

Equipped with additional tradition control panel. |

|

Reserved space for built-in auto flux spraying machine. |

|

| Two sections program setting for weekly timer. |

| |

|

| |

|

|

|

|

Additional Tradition Control Panel |

|

|

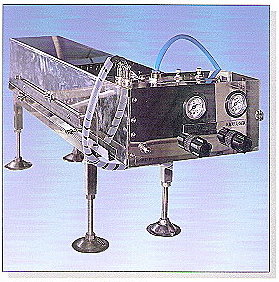

SE-420-SP Built In Flux Sprayer |

|

|

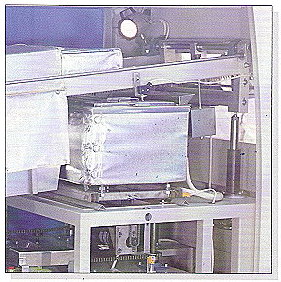

Hot Air System, Solder Pot & Cooling Fan (Patent) |

|

|

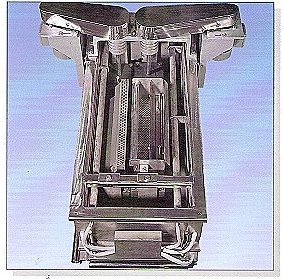

| Unleaded High Pressure Solder Wave Nozzle & Solder Pot(Patent) |

|

|